Home > Textbooks > Basic Electronics > Capacitors > Capacitor Types >

Capacitors

Capacitor Types

In electrical and electronic equipment, it is very often necessary to use capacitors for coupling the signal between amplifier stages, bypassing the signal away from various elements, decoupling stages, filtering ripple from power supplies, forming complex signal filter networks, and forming tuned circuits for oscillators and amplifiers. In these various applications the equipment designer has a choice of two broad groups of capacitor types: fixed and variable. Details concerning the wide variety of commercial types will be discussed in this section.

Fixed Capacitors

A fixed capacitor is constructed in such manner that it possesses a fixed value of capacitance which cannot be adjusted. A fixed capacitor is classified according to the type of material used as its dielectric, such as paper, ceramic, mica, or electrolyte.

Paper Capacitors

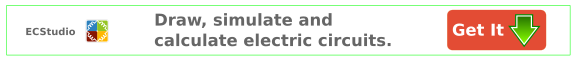

A paper capacitor is made of flat thin strips of metal foil conductors that are separated by waxed paper (the dielectric material). Paper capacitors usually range in value from about 100 picofarads to about 10 microfarads. The working voltage of a paper capacitor rarely exceeds 600 volts. Paper capacitors are sealed with wax to prevent the harmful effects of moisture and to prevent corrosion and leakage.

Many different kinds of outer covering are used on paper capacitors, the simplest being a tubular cardboard covering. Some types of paper capacitors are encased in very hard plastic. These types are very rugged and can be used over a much wider temperature range than can the tubular cardboard type. The figure below shows the construction of a tubular paper capacitor.

Film Capacitors

Here the dielectric material is a plastic film employed alone or as a laminate with paper. The film has high mechanical strength, long-term resistance to heat, and chemical inertness if hermetically sealed. Materials commonly used are polypropylene, polystyrene and polyethelyne. The roll construction of film-type capacitors is the same as paper capacitors.

Mica Capacitors

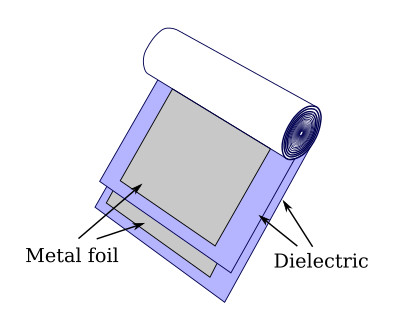

The basic construction of a mica capacitor is shown in the figure below. It consists of a number of flat strips of metal foil separated by similarly shaped strips of mica. The foil strips serve as the capacitor plates, and the mica acts as the dielectric. Alternate plates are connected together. The whole assembly is encased in molded plastic.

An alternate construction is that of the "silvered" mica capacitor. In this construction very thin layers of silver are deposited directly upon one side of the mica, and the plates are stacked together so that alternate layers of silver are separated by alternate layers of mica. The result is the equivalent of the foil construction. This method enables closer manufacturing tolerances to be met, since precision masking techniques permit the area of the deposited plate to be determined with greater accuracy and greater uniformity than in the cut-foil construction. In addition, the thickness of the completed capacitor is less, due to the thinness of the deposited plate.

Mica is an excellent dielectric and can withstand a higher voltage than can a paper dielectric of the same thickness. Common values of mica capacitors range from approximately 10 pF to 100 nF.

Ceramic Capacitors

A ceramic capacitor is so named because it contains a ceramic dielectric. One type of ceramic capacitor uses a hollow ceramic cylinder as both the form on which to construct the capacitor and as the dielectric material. The plates consist of thin films of metal deposited on the ceramic cylinder.

A second type of ceramic capacitor is manufactured in the shape of a disk. The construction consists of a ceramic disc with metal plates deposited on the opposite faces of the ceramic material. After leads are attached to each side of the capacitor, the capacitor is completely covered with an insulating moisture-proof coating. Ceramic capacitors usually range in value from 1 pF to 100 nF and may be used with voltages as high as 30 kV.

Electrolytic Capacitors

An electrolytic capacitor is used where a large amount of capacitance is required. As the name implies, an electrolytic capacitor contains an electrolyte. This electrolyte can be in the form of a liquid (wet electrolytic capacitor). The wet electrolytic capacitor is no longer in popular use due to the care needed to prevent spilling of the electrolyte. A dry electrolytic capacitor consists essentially of two metal plates separated by the electrolyte. In many cases the capacitor is housed in a cylindrical aluminum container which acts as the negative terminal of the capacitor. The positive terminal (or terminals if the capacitor is of the multisection type) is a lug (or lugs) on the bottom end of the container. The capacitance value(s) and the voltage rating of the capacitor are generally printed on the side of the aluminum case.

Internally, the electrolytic capacitor is constructed similarly to the paper capacitor. The positive plate consists of aluminum (or tantalum) foil covered with an extremely thin film of oxide. This thin oxide film (which is formed by an electrochemical process) acts as the dielectric of the capacitor. Next to and in contact with the oxide is a strip of paper or gauze which has been impregnated with a paste-like electrolyte. The electrolyte acts as the negative plate of the capacitor. A second strip of aluminum foil is then placed against the electrolyte to provide electrical contact to the negative electrode (the electrolyte). When the three layers are in place they are rolled up into a cylinder.

An electrolytic capacitor has two primary disadvantages compared to a paper or film capacitor in that the electrolytic type is polarized and has a low leakage resistance. This means that should the positive plate be accidentally connected to the negative terminal of the source, the thin oxide film dielectric will dissolve and the capacitor will become a conductor (i.e., it will short). The polarity of the terminals is normally marked on the case of the capacitor. Since an electrolytic capacitor is polarity sensitive, its use is ordinarily restricted to a DC circuit or to a circuit where a small AC voltage is superimposed on a DC voltage. Special electrolytic capacitors are available for certain AC applications, such as a motor starting capacitor. Dry electrolytic capacitors vary in size from about 1 microfarad to several thousand microfarads.

The type of dielectric used and its thickness govern the amount of voltage that can safely be applied to the electrolytic capacitor. If the voltage applied to the capacitor is high enough to cause the atoms of the dielectric material to become ionized, arcing between the plates will occur. In most other types of capacitors, arcing will destroy the capacitor. However, an electrolytic capacitor has the ability to be self-healing. If the arcing is small, the electrolytic will regenerate itself. If the arcing is too large, the capacitor will not self-heal and will become defective.

Variable Capacitors

A variable capacitor is constructed in such manner that its value of capacitance can be varied. There are two versions of variable capacitors: tuning and trimmer.

Tuning Capacitors

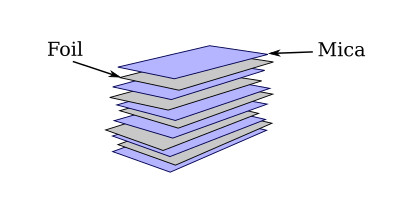

In a number of applications the equipment operator must tune his/her equipment by changing capacitance over a fairly wide range. A typical tuning capacitor is the rotor-stator type. It consists of two sets of metal plates arranged so that the rotor plates move between the stator plates. Air is the dielectric. As the position of the rotor is changed, the capacitance value is likewise changed. Care is taken in the design and manufacture of these capacitors to secure ease and smoothness of rotation along with an accurately predictable variation throughout the full range of rotation. This type of capacitor is usually used for tuning radio receivers. Its physical appearance is shown in the figure below.

Trimmer Capacitors

There are applications, such as certain types of tuned circuits, in which the exact value of capacitance required in the circuit cannot be predicted or controlled with the required accuracy. In such applications, it is helpful to have available a capacitor which can be adjusted to the exact required value when the equipment is aligned after assembly. Adjustment by the equipment user is unnecessary, although a later adjustment may have to be made by a service technician during equipment servicing. Since the capacitor does not require frequent resetting, no special pains are taken to make this adjustment particularly convenient, and the range of adjustment is generally quite small.

One type of trimmer capacitor is shown in the figure below. A screw adjustment is used to change the capacitance of this capacitor.